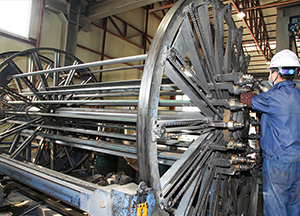

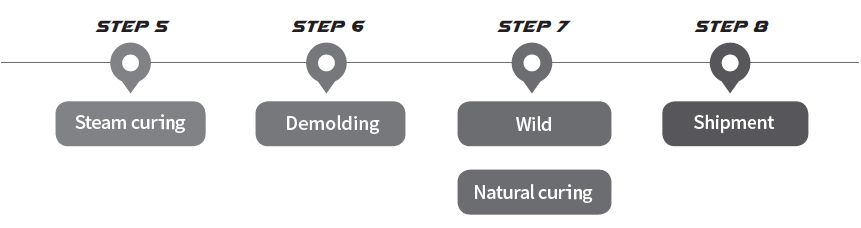

Manufacturing Process

( centrifugal Reinforced Concrete Pipe )

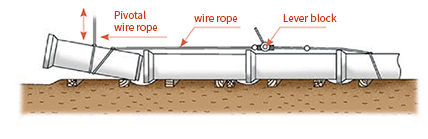

Construction ( pulling )

Inspection on Pipe

-

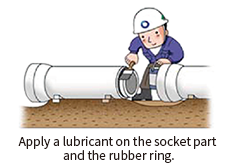

- Clean and check the socket part and the SPICOAT part.

- Install the rubber ring correctly.

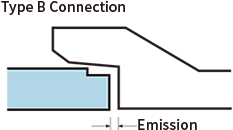

- Accepted length of emission (distance)

Connection

Allowed emission for different sizes (Type B)(Unit:mm)

-

Nominal Diameter Allowed procession 250 10 ~ 15 300 10 ~ 15 350 10 ~ 15 400 11 ~ 17 450 11 ~ 17 500 11 ~ 17 600 13 ~ 20 -

Nominal Diameter Allowed procession 700 13 ~ 20 800 13 ~ 20 900 15 ~ 20 1000 18 ~ 20 1100 19 ~ 20 1200 21 ~ 31 1350 22 ~ 33

※ The above amount is from 1/3 to 1/2 of maximum emission. However, if there is a risk of ground subsidence, set it as small as possible, and the maximum emission applies when the ground is in good quality.

Connection Method

-

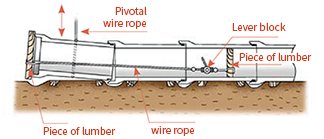

When the nominal diameter is not more than 700: The wire rope is supported by the pipe which is a couple of pipes away and is already laid.

-

When the nominal diameter is not more than 800: The wire rope is supported by the pipe which is a couple of pipes away and is already laid.

Fixation

-

- After connecting it completely, untangle the wire rope for balancing.

- Fix the pipe completely and unwind the joint device.

Refilling

-

- After completing connection and fixation, refill the emptied area immediately.

- Use sand or high-quality soil for refilling.

- Divide layers and firm each layer (30 cm) while refilling.

-

- Be careful not to make any gaps on the lower part of the pipe.

- Firm the sand of the both sides of the pipe evenly.

- Firm the whole area that was excavated.

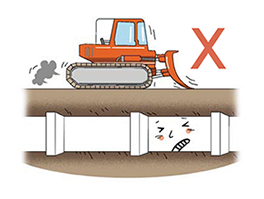

Caution

-

- Do not pour soil for refilling at once with bulldozers, dump trucks, etc.

-

- Do not let construction machines directly move on the top of the installed pipe